The unique manufactory in the Swiss Alps

In the middle of the Valais Alps at almost 900 meters above sea level, very close to the Matterhorn, you will find the unique eyewear manufactory in Switzerland.

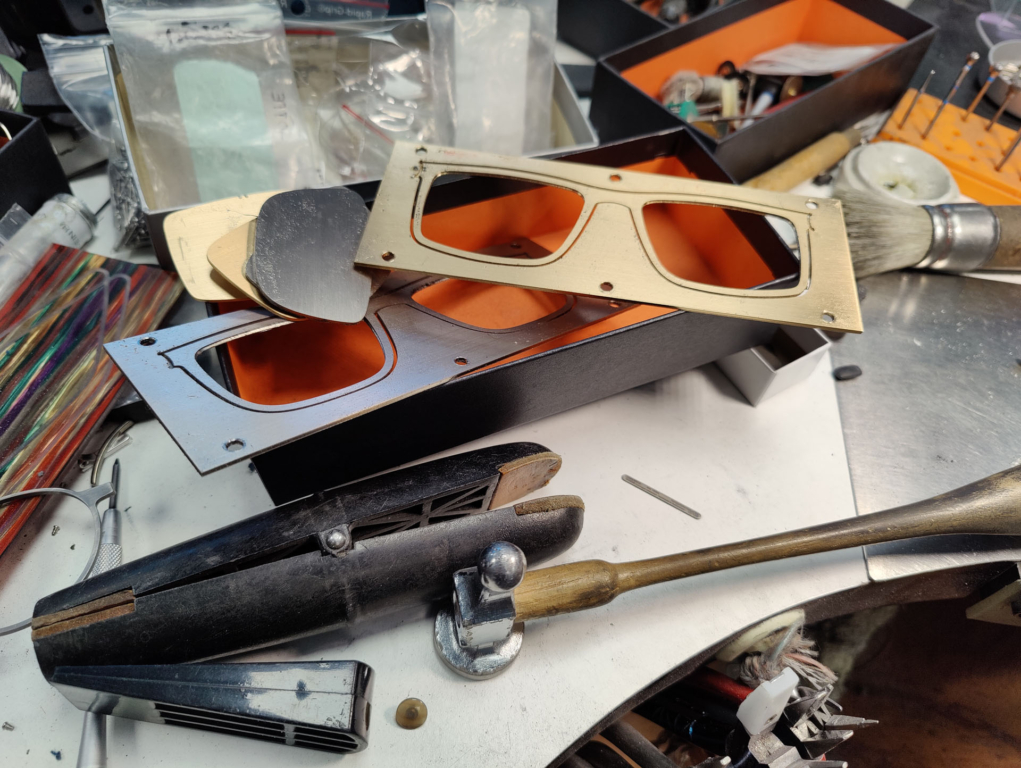

Founded in 1992 by Caroline and Marcus Marienfeld, the company now has a team of 7 employees and produces five eyewear collections that build on each other, from the mid-range segment to the high-end segment and frames in precious metals. Materials such as titanium, Indian water buffalo horn, unidirectional carbon, as well as the precious metal 18kt gold form the basis of these frames. State-of-the-art five-axis CNC technology supports the original craftsmanship practiced. Goldsmiths and watchmakers use their expertise to manufacture these high-quality products – 100% handmade in Switzerland.

The enclave of the Swiss Alps is a motivator and guaranty of innovation and quality.

Materials

pure titanium

Titanium can already be found in our periodic table as a pure material. It stands for wonderful lightness and at the same time maximum stability, it is anti-allergic and therefore even suitable for implants. However, its very difficult in processing. It is tough and requires a lot of tools. But it is stabile and it is processed absolutely nickel-free thanks to our pure laser connection technology. Even its color coating is anti-allergic as a pure titanium nitride layer, which only makes the very complex and therefore very expensive PVD coating possible.

indian water buffalo horn

Our long-standing contacts with Indian horn suppliers guarantee the best quality for our buffalo horn raw material. Once it arrives at our manufactory, it is stored for two years in our wine cellars. It matures, so to speak, at a humidity of between 70 and 80% before we process it into spectacle frames. After this time, the horn shows us its original shape. This is because, contrary to its nature, it is often literally raped by boiling and then pressing. Such plates always want to return to their original shape, i.e. the finished frame would reshape itself. This is exactly what you will never will find with a Marienfeld buffalo horn frame, as we only allow homogeneous horn to become spectacle frames. Discarded horn plates are not thrown away, but are shaped into our unique buffalo horn pads, which our titanium frames use as natural nose pads.

unidirectional carbon

Carbon fiber is the basis and guarantor of maximum stability and incredible lightness. This is why we often find carbon in technical products, for example in the automotive industry. Here it is mostly used as a fabric. For aesthetic reasons, however, we use it unidirectionally, with the fibers running in one direction. A rather difficult undertaking, as it turned out. Especially as we did not want to use epoxy resins. In addition, our carbon components are not painted, which enables an exceptionally high level of light reflection. The light literally travels over our frames, which creates a wonderful vibrancy on what initially appears to be a rather technical product.

18kt Gold

Marcus Marienfeld AG exclusively uses OEKOGOLD from our partner, GYR Edelmetalle AG. Christophe Gyr guarantees that only recycled gold is given the OEKOGOLD label. Fine gold refined from old gold is re-alloyed and offered as new sheet and wire. We manufacture our high-quality gold eyewear exclusively from these unique basic materials. Sustainability is practiced intensively here and has been from the very beginning of our work, when nobody was talking about sustainability.

3D print

Our 3D printed fronts of collections ASP3D – Aspekte 3D and MM3D – Marcus Marienfeld 3D are realized using the laser sintering process. Many hundreds of layers are used to create the products in 3D printing. Three-dimensional drawings generated in our CAD system serve as the basis. We print exclusively in black, carbon fiber-reinforced PA12 nylon powder of the best quality and thus obtain a homogeneous 3D printed product.